My transformation from urban dweller to urban farmer didn’t happen in a lush backyard. It happened on a 4×6 balcony overlooking a parking garage, with more cigarette butts than sunlight. I was determined to grow my own food, but traditional gardening was impossible in my limited space. Through months of experimentation, catastrophic failures, and eventual breakthroughs, I discovered the power of vertical hydroponics.

The turning point came when my first DIY tower—built from cheap PVC—buckled under the weight of 12 romaine lettuce plants, flooding my balcony and earning me a stern letter from building management. That failure taught me more about structural engineering than any tutorial. Today, that same space produces over 40 plants simultaneously, supplying my household with fresh greens and even generating surplus for neighbors.

This isn’t just another vertical gardening guide. This is a battle-tested blueprint for transforming any urban space into a highly productive food system. I’ve made the mistakes so you don’t have to, and I’m sharing every lesson learned from building and maintaining multiple vertical systems in truly challenging environments.

Why Vertical Hydroponics Beats Traditional Gardening Every Time

The Space Multiplication Effect

Urban spaces demand innovative solutions. While traditional gardening operates in two dimensions (length × width), vertical hydroponics adds the critical third dimension: height. This simple shift in perspective changes everything about urban food production.

Consider the math: A standard 2′ × 2′ footprint can support a 6-foot tall tower containing 20-24 plants. Compared to soil gardening in the same footprint—which might support 4-6 plants at most—this represents a 400-500% increase in production capacity. For urban dwellers working with balconies, rooftops, or even bright indoor corners, this space efficiency transforms what’s possible.

The Hidden Benefits Beyond Space Savings

While space efficiency gets attention, vertical hydroponics offers several underappreciated advantages:

- Ergonomic Harvesting: No more bending or kneeling. Towers bring plants to waist level, making maintenance and harvesting accessible for those with mobility challenges.

- Pest Reduction: Elevated growing positions and soilless media significantly reduce problems with soil-borne pests and diseases.

- Water Efficiency: Hydroponic systems recirculate water, using up to 90% less than soil gardening while delivering nutrients directly to roots.

- Year-Round Production: Indoor-compatible systems defy seasons, providing fresh food regardless of weather conditions outside.

System Showdown: Choosing Your Vertical Growing Strategy

Deep Water Culture (DWC) Towers: Simplicity Meets Performance

Often overlooked but incredibly effective, DWC towers represent perhaps the most reliable entry point into vertical hydroponics. These systems suspend plant roots in oxygen-rich nutrient solutions, creating ideal growing conditions with minimal complexity.

How It Works: Plants sit in net pots mounted on a floating platform (typically styrofoam) that rides on the surface of a nutrient solution. A simple air pump and air stone oxygenate the water, preventing root rot and promoting explosive growth.

Why It Works So Well: The constant access to both nutrients and oxygen creates ideal growing conditions. Roots never experience drought stress or nutrient deficiency when properly maintained.

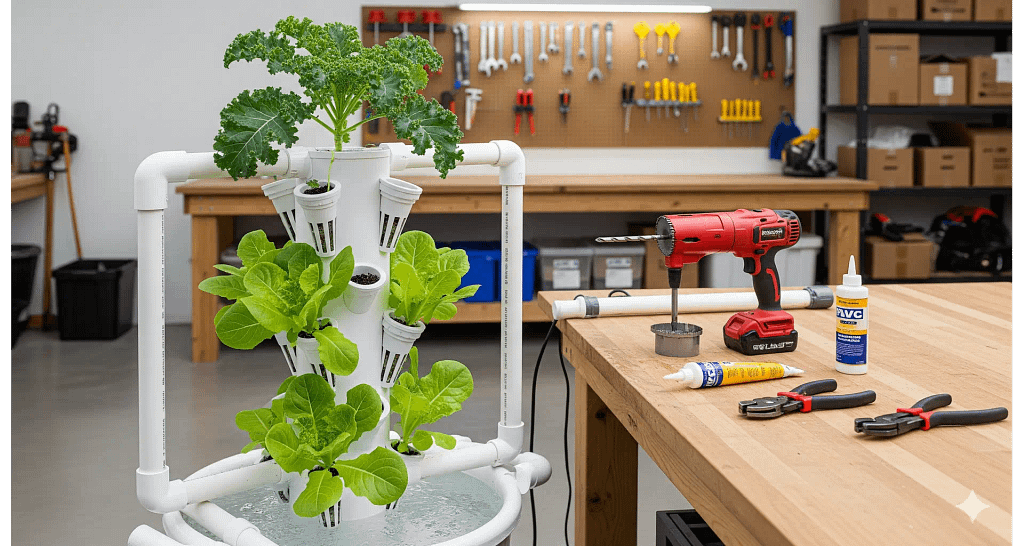

Nutrient Film Technique (NFT): The Balanced Approach

NFT systems strike an ideal balance between efficiency and reliability, making them popular among commercial growers and serious home gardeners alike.

The Mechanics: A shallow stream of nutrient solution flows continuously through slightly angled channels, creating a thin “film” that keeps roots moist while exposing their upper portions to oxygen-rich air.

Implementation Hack: For DIY builders, create a “flow distributor” at the top of your tower using a plastic container with multiple small holes. This ensures even water distribution across the entire channel width, preventing dry spots that can develop in homemade systems.

Aeroponics: The High-Performance Option

For those seeking maximum growth rates and willing to accept increased complexity, aeroponic systems represent the cutting edge of vertical farming technology.

How It Works: Plant roots hang in dark chambers where they’re periodically misted with nutrient solution. This approach provides optimal oxygen access while delivering nutrients directly to root surfaces.

The Challenge: Aeroponics demands greater precision than other systems. Nozzles can clog, pumps must maintain adequate pressure, and power failures can be catastrophic without backup systems.

The Structural Foundation: Building Towers That Won’t Fail

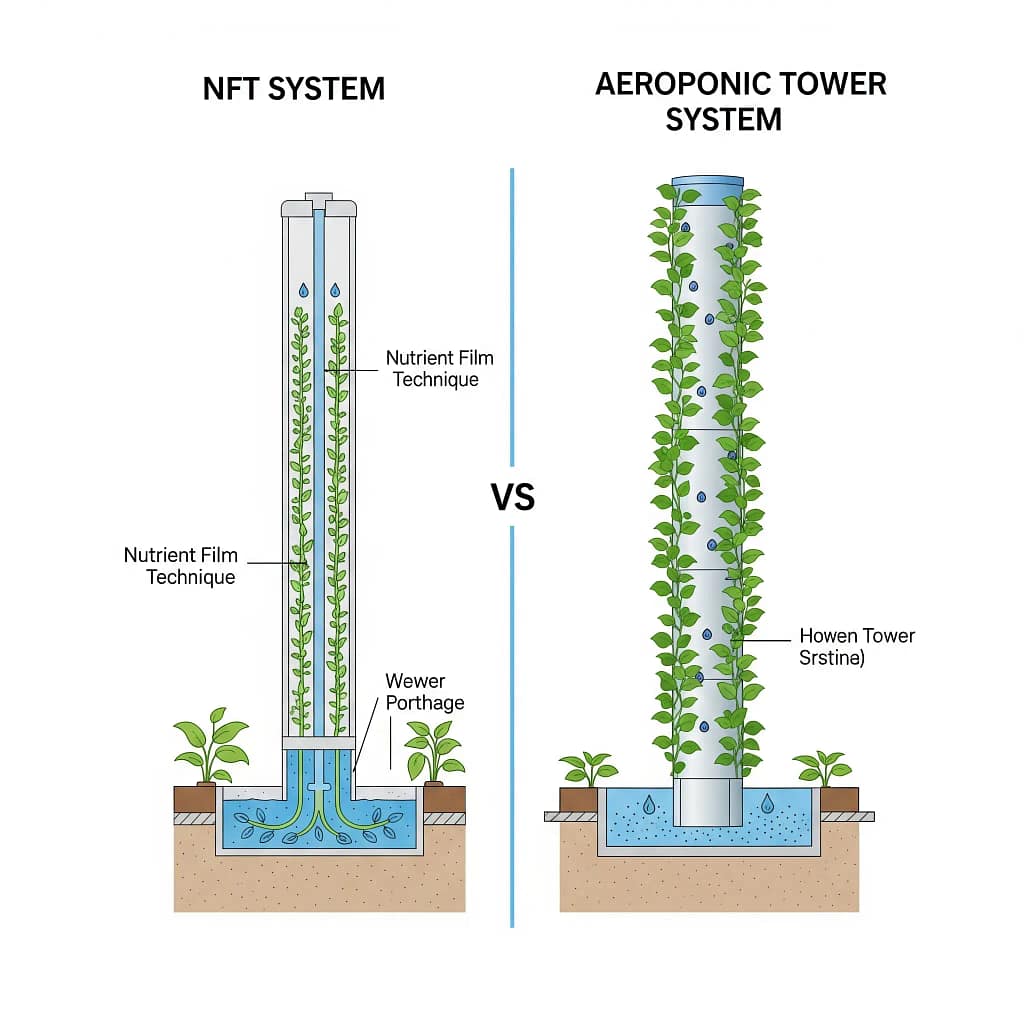

Material Selection: Beyond Basic PVC

While PVC pipe represents the most common DIY approach, several alternatives offer distinct advantages:

UV-Stabilized ABS Pipe: Slightly more expensive than PVC but offers superior UV resistance and structural integrity. Essential for outdoor systems in sunny locations.

Vinyl Fence Posts: These 4″×4″ posts provide excellent rigidity and light-blocking properties. Their square profile makes mounting plants easier than round pipes.

Food-Grade Buckets: For DWC systems, food-grade buckets offer proven safety and durability. Their opaque walls prevent algae growth while containing nutrients effectively.

Engineering for Load Capacity

Vertical systems must support significant weight—not just from plants, but from water-soaked growing media and the nutrient solution itself. Underestimating this load represents the most common failure point in DIY systems.

Weight Calculation Formula:

- Plant weight: 1-2 lbs per mature plant (leafy greens)

- Growing media: 0.5-1 lb per net pot

- Water weight: 8.3 lbs per gallon

A 20-plant tower can easily exceed 100 lbs when fully operational. Design accordingly.

Reinforcement Strategy: For tall towers (over 4 feet), incorporate structural supports every 24-36 inches. Unistrut metal framing or treated wood braces can prevent the bowing and collapse that doomed my first system.

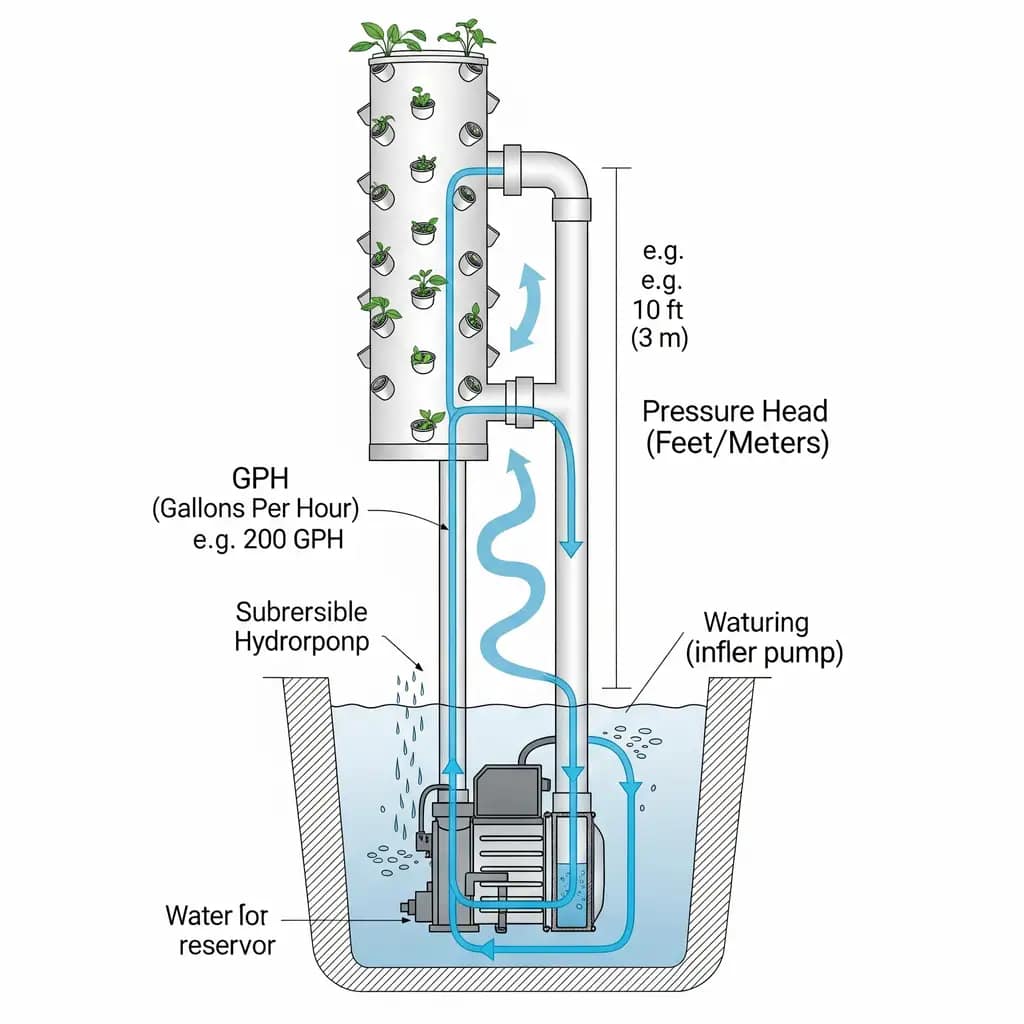

The Heart of the System: Pump Selection and Hydraulics

Understanding Pump Specifications

Choosing the wrong pump represents perhaps the most expensive mistake in hydroponics. Understanding key specifications prevents this error:

Flow Rate (GPH): Calculate based on system volume—your pump should circulate the entire nutrient solution at least once per hour. For most home systems, 200-400 GPH proves sufficient.

Head Height: This critical specification indicates how high a pump can push water. Always choose a pump with a maximum head height 25% greater than your actual system height to account for friction losses.

Energy Efficiency: DC-powered pumps often provide better energy efficiency than AC models, particularly valuable for systems running 24/7.

- Specs & Dimensions: 4.33*3.5*4.1 inches; Max flow rate: 800 GPH (3000L/H); Max lift height: up to 10 ft.; Wattage: 24W; …

- Adjustable Flow Rate: Water flow can be adjusted via the control knob and change different nozzles to meet the water pre…

- Detachable & Cleanable: This powerful yet small-sized water pump is easy to hide and disguise; No tools are necessary fo…

The Silent Killer: Heat Transfer

Submersible pumps transfer heat directly into nutrient solutions, potentially raising temperatures to levels that promote root disease and reduce oxygen solubility.

Solution: Place pumps in separate sump reservoirs rather than main growing containers. This isolates heat while maintaining proper circulation. Alternatively, use external pumps that keep heat entirely outside the system.

- Pressure Pump: With an open flow rate of 4.0 GPM and the ability to self-prime up to 9.8 feet, this 110V diaphragm pump …

- Automatic Pressure Switch: The rated pressure is set at 50 PSI. With its failure-free control, the water pump will autom…

- Security You Can Trust: Self Priming up to 9.8 vertical feet, lift up to 148 feet. Thermal overload protection is built …

Plant Selection Strategy: Matching Crops to Vertical Systems

High-Performance Vertical Crops

Through extensive testing, I’ve identified ideal candidates for vertical cultivation:

Leafy Greens: Lettuces, kale, spinach, and chard thrive in vertical systems. Their relatively small root systems and rapid growth cycles make them perfect for high-density planting.

Herbs: Basil, cilantro, mint, and oregano adapt exceptionally well to vertical growing. The elevated positioning often improves air circulation around these disease-prone plants.

Strawberries: Perhaps the ideal vertical crop, strawberries benefit from clean, elevated growing conditions that reduce fungal issues and make harvesting effortless.

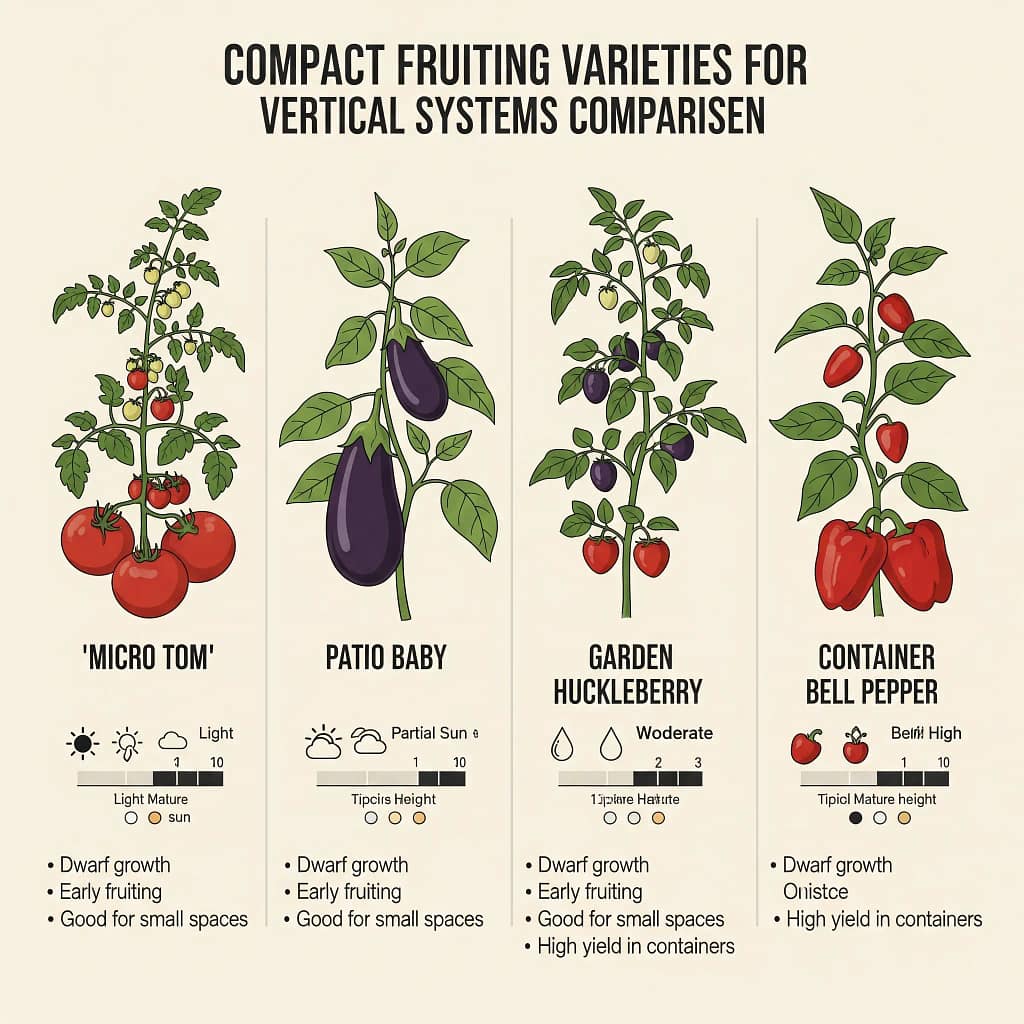

Dwarf Varieties: Specifically bred compact versions of tomatoes, peppers, and eggplants can work in larger vertical systems, though they require substantial structural support.

Plants to Avoid in Vertical Systems

Despite what some enthusiasts claim, certain plants prove poorly suited for vertical cultivation:

Large Fruiting Plants: Full-sized tomatoes, peppers, and eggplants develop extensive root systems and heavy fruit loads that most vertical systems cannot support.

Root Crops: Carrots, potatoes, and other root vegetables simply don’t work in typical vertical setups despite claims to the contrary.

Vining Plants: While cucumbers and beans can be trained upward, their aggressive growth quickly overwhelms nearby plants in dense vertical plantings.

- USDA Certified Organic by Oregon Tilth

- 10 varieties of leafy salad greens seeds packed fresh for the current and following year

- Green Towers Romaine (Lactuca sativa), Winter Density (Lactuca sativa), Dark Lolla Rossa (Lactuca sativa), Black Seeded …

- 🍓 Grow Extra Big, Juicy Strawberries – Enjoy large, sweet, and flavorful strawberries, perfect for fresh eating, dessert…

- 🍓 Non-GMO & Heirloom Variety – 100% natural, open-pollinated seeds with no genetic modification, ensuring authentic tast…

- 🍓 Ideal for Any Growing Space – Perfect for gardens, pots, raised beds, balconies, greenhouses, or vertical planters, ma…

Advanced Nutrient Management for Vertical Systems

The Recirculation Challenge

Unlike single-container systems, vertical towers present unique nutrient management challenges as solution passes multiple root zones sequentially.

Solution Strategies:

- Increased Flow Rates: Faster circulation minimizes concentration differences between top and bottom plants.

- Strategic Plant Placement: Place heavy feeders at the top of the system, lighter feeders at the bottom.

- Frequent Solution Changes: More frequent nutrient changes prevent severe depletion issues.

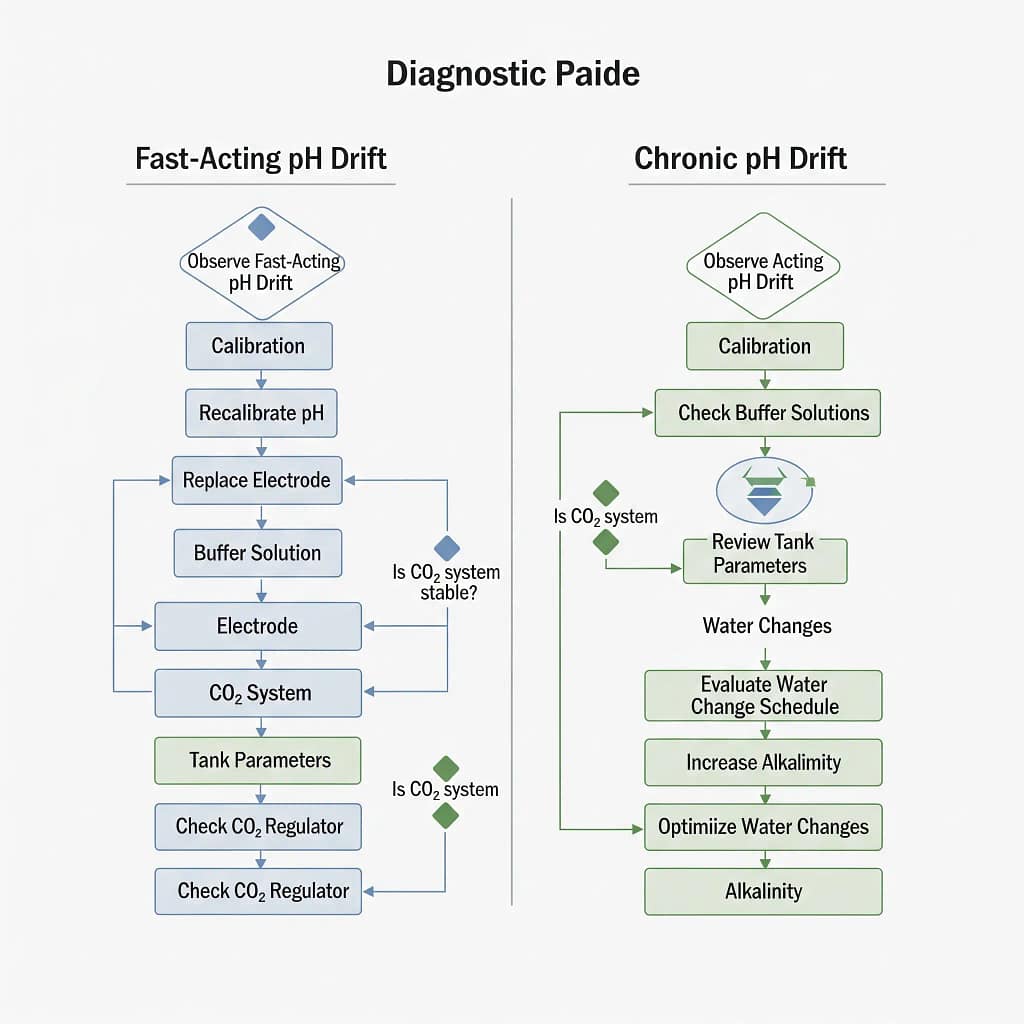

pH and EC Management Protocol

Maintaining stable parameters proves more challenging in vertical systems due to the nutrient depletion effect.

Monitoring Protocol:

- Check pH and EC daily

- Sample from both top and bottom of system

- Adjust based on the average reading

Stabilization Techniques:

- Use pH-buffered nutrients specifically designed for recirculating systems

- Incorporate beneficial microbes to create more stable root zones

- Maintain solution temperature between 65-72°F for optimal nutrient uptake

- The Flora Series is a hydroponic-based nutrient system that helps fulfill your plants’ nutrient needs at every stage of …

- Nutrients included in the Series are FloraMicro, FloraBloom, and FloraGro

- FloraMicro: contains nitrogen and calcium, as well as trace minerals, which are essential for a comprehensive hydroponic…

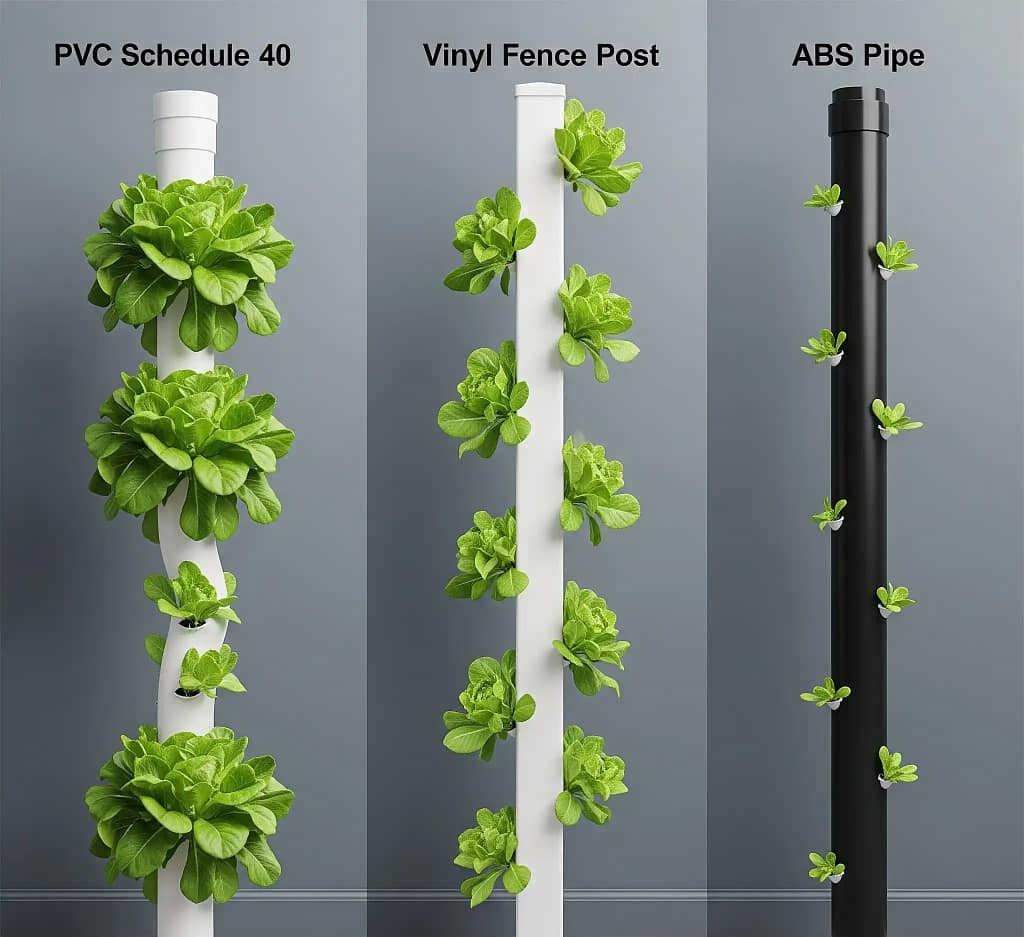

DIY Construction: Building Your First Professional-Grade Tower

Step-by-Step NFT Tower Construction

Follow this proven design for a reliable, high-performance system:

Materials List:

- 4″ UV-resistant PVC pipe (5-6 feet length)

- 20-24 net pots (2″ size)

- 10-gallon reservoir with lid

- 400 GPH submersible pump with 8+ foot head height

- 1/2″ black tubing and associated fittings

- Hole saw kit (2″ and 1/4″ sizes)

- Food-grade silicone sealant

Construction Process:

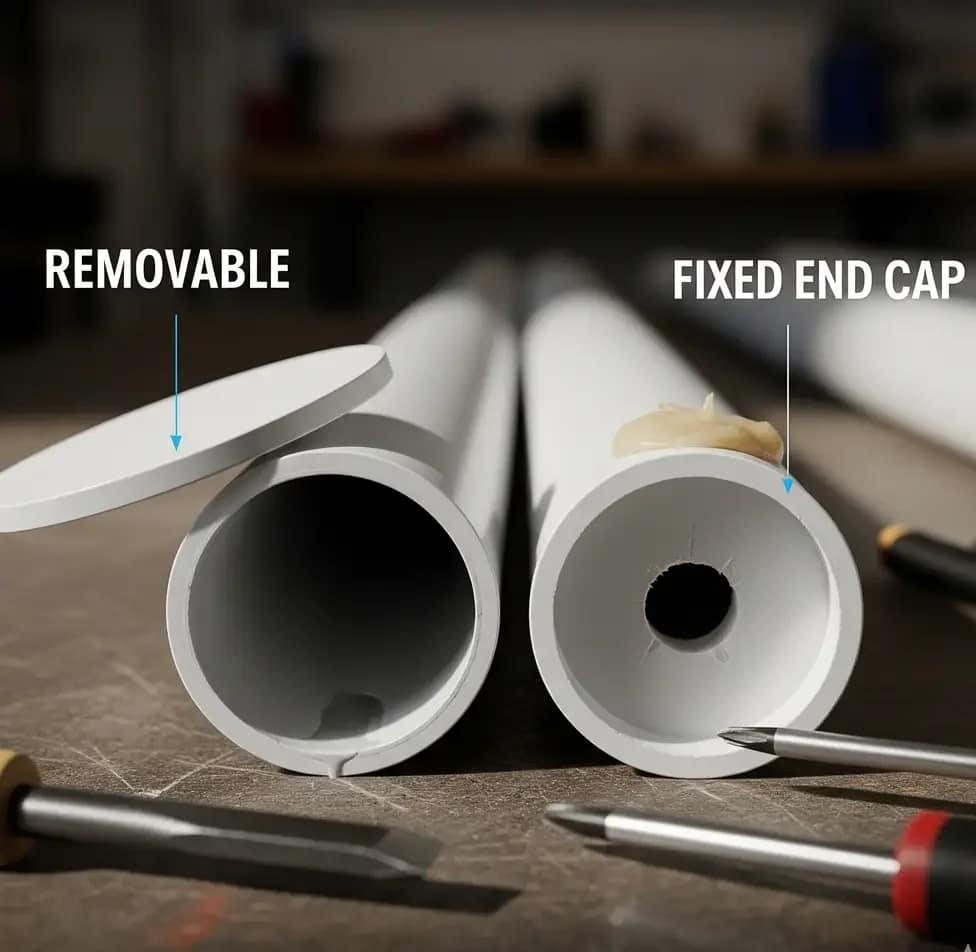

- Marking and Drilling: Mark hole positions in a staggered pattern with 6-8 inch vertical spacing. Drill at a 15-degree downward angle to prevent water channeling.

- Reservoir Modification: Cut an appropriate hole in the reservoir lid for the main tower and a smaller hole for return flow.

- Flow Distribution System: Create a distribution manifold at the top of the tower using a PVC end cap drilled with multiple small holes. This ensures even water flow across the entire channel.

- Leak Prevention: Apply food-grade silicone around all fittings and connections. Allow 24-48 hours for complete curing before adding water.

- Final Assembly: Place the pump in the reservoir, connect tubing, and do a water test without plants to identify any leaks or flow issues.

- 8 oz. PTFE thread sealant

- Multi-purpose, heavy-duty sealant fills gaps and imperfections

- For use on all metals, PVC, CPVC and ABS plastics

Maintenance Mastery: Keeping Your System Flawless

Daily Monitoring Protocol

Consistent monitoring prevents small issues from becoming system failures:

Morning Checklist:

- Visual inspection of plants and roots

- pH and EC measurement and adjustment

- Pump operation verification

- Temperature check (air and water)

Evening Checklist:

- Visual inspection for pests or abnormalities

- Reservoir level check

- System noise assessment (unusual sounds often indicate pump issues)

Weekly Maintenance Tasks

These essential tasks require 30-60 minutes weekly but prevent most common problems:

- Complete System Flush: Drain and replace nutrient solution to prevent salt buildup and nutrient imbalance.

- Root Inspection: Check for discoloration, sliminess, or other signs of disease. Healthy roots should be white or light tan with numerous fine hairs.

- Pump Maintenance: Clean pre-filters and inspect for wear. Monthly, disassemble and clean impeller chambers.

- Algae Prevention: Wipe down exposed surfaces and check for light leaks into the system.

Monthly Deep Cleaning

Once monthly, perform a complete system sterilization:

- Remove plants and gently rinse roots

- Drain and scrub reservoir with hydrogen peroxide solution

- Flush all tubing with cleaning solution

- Sterilize net pots and growing media

- Reassemble with fresh nutrient solution

- Measures pH in nutrient solution (acid or alkaline) for precise up and down adjustment and is used with meters; General …

- 2 meter / 6.56 foot standard cable, easy calibration, fully waterproof including cable joint, easy to clean and maintain

- Double junction probe has a longer lifespan compared to standard probes due to less contamination and is more accurate a…

Troubleshooting Common Vertical System Issues

Identifying and Solving Plant Problems

- Yellowing Lower Leaves: Typically indicates nitrogen deficiency, often exacerbated by the nutrient depletion gradient. Increase nutrient strength or add supplemental nitrogen.

- Stunted Growth: Usually caused by root zone issues—check temperature, oxygen levels, and for root disease.

- Tip Burn: Frequently indicates calcium deficiency, often related to poor transportation within the plant rather than lack of calcium in solution. Improve air flow and reduce humidity.

System-Specific Issues

- Clogging Problems: Install inline filters before pumps and use clean, debris-free nutrients. For aeroponic systems, use self-cleaning nozzles.

- Uneven Water Distribution: Check for level installation and ensure proper pump capacity. Add additional distribution points if necessary.

- Temperature Fluctuations: Use reservoir insulation and consider water chillers or heaters for extreme climates.

Scaling Up: From Single Tower to Urban Farm

Multi-Tower System Design

Once you’ve mastered a single tower, expanding requires careful planning:

- Lighting Considerations: Position towers to prevent shading—south-facing arrangements work best for natural light, while artificial lighting requires careful spacing calculations.

- Irrigation Efficiency: Use a central reservoir for multiple towers to simplify maintenance and improve temperature stability.

- Structural Support: Ensure your balcony or growing area can handle the weight of multiple systems—water weighs approximately 8.3 pounds per gallon.

Automation Opportunities

As you expand, consider these automation upgrades:

- Dosing Systems: Automatic pH and nutrient controllers maintain perfect conditions with minimal intervention.

- Lighting Control: Programmable timers ensure consistent light cycles for optimal growth.

- Remote Monitoring: WiFi-enabled sensors provide real-time system data to your smartphone.

- Complete grow tent kit that features integrated AI controls with precision equipment and Athena simplified fertilizers.

- Controller AI+ observes and learns the best configurations to automate each device to its most optimal settings for plan…

- Control your setup from anywhere via WIFI with our app, featuring real-time AI insights, guides, alerts, charts, and the…

Conclusion: Your Urban Farming Journey Begins Now

Vertical hydroponics represents more than just a gardening technique—it’s a paradigm shift in how we think about food production in limited spaces. The journey from my failed PVC tower to a productive urban food system taught me that success lies not in avoiding failures, but in learning from them systematically.

The system outlined here has been refined through years of experimentation and optimization. While it requires an initial investment of time and resources, the return—in fresh food, self-sufficiency, and the simple satisfaction of growing your own nourishment—proves invaluable.

Start small with a single tower, master the principles, and expand as your confidence grows. The vertical frontier awaits, and your urban food revolution begins with that first hole drilled, first pump installed, first seed germinated. The concrete jungle is about to get a lot greener.

Vertical Hydroponics FAQs

Q: Is a vertical hydroponic system difficult for a beginner to build?

A: It depends on the system design. A simple Deep Water Culture (DWC) bucket system is a fantastic and almost foolproof project for a true beginner. A full-scale Nutrient Film Technique (NFT) or aeroponic tower requires intermediate DIY skills, including drilling, sealing, and basic plumbing. Start with a single DWC bucket to learn the principles of hydroponics before scaling up to a complex vertical tower.

Q: What is the most common mistake beginners make when building their first tower?

A: Underestimating structural weight and pump power. The most common catastrophic failure is a tower bowing or collapsing under the weight of water-soaked growing media and mature plants. The second biggest mistake is choosing a pump with insufficient “head height” (vertical lifting power), which starves the top plants of water and nutrients. Always over-engineer for weight and double-check your pump’s head rating against your tower’s height.

Q: I don’t have a balcony. Can I run a vertical hydroponic system indoors?

A: Absolutely. Indoor vertical systems are highly effective, but they require investment in full-spectrum LED grow lights. The key is to choose a system that fits your space and has adequate lighting for the plants you want to grow. You’ll also need to be more diligent about humidity control and air circulation to prevent mold and mildew indoors.

Q: How often do I really need to check the pH and nutrient levels?

A: For a stable, established system, checking every 2-3 days is sufficient. However, when you first set up your system or after a nutrient change, check daily for the first week to understand how your system behaves. The goal is consistency. Dramatic swings in pH or EC (Electrical Conductivity) are more harmful to plants than a slightly imperfect value.

Q: Are there any plants that should NEVER be grown in a vertical hydroponic system?

A: Yes. Avoid large, heavy, and deep-rooting plants.

– Large Fruiting Plants: Full-sized tomatoes, peppers, and eggplants are too heavy and will topple your tower.

– Root Vegetables: Carrots, potatoes, onions, and radishes need deep, loose substrate to form properly, which isn’t compatible with net pots.

– Vining Plants: While possible, vining plants like cucumbers and pole beans can quickly create a tangled, shaded mess that overwhelms the structure and other plants.

Q: How do I prevent algae growth in my system?

A: Algae needs light and nutrients to grow. Starve it of light.

– Use Opaque Materials: Always use black, dark blue, or otherwise light-proof containers and tubing.

– Cover Exposed Surfaces: Use light-proof lids on your reservoir and cover any exposed growing medium (like clay pebbles) with a foil or plastic cap.

– Maintain Your System: Regular cleaning and using a product like food-grade hydrogen peroxide in your reservoir (at 3ml per gallon) can help kill algae without harming your plants.

Q: What’s the single most important factor for success with vertical hydroponics?

A: Consistency. Unlike soil, which buffers mistakes, hydroponics is a high-performance system that reacts quickly to changes. The most successful growers are those who are consistent with their maintenance—checking pH, monitoring nutrients, cleaning filters, and inspecting plants. A little daily attention prevents 95% of all potential problems.

Q: Can I use regular garden fertilizer in my hydroponic system?

A: No, this is a critical mistake. Regular garden fertilizers are designed for soil and contain insoluble compounds that will clog your pumps and drip emitters. They also lack the precise balance of micronutrients that plants need in a soilless environment. You must use fertilizers specifically formulated for hydroponics, as they are water-soluble and contain a complete nutrient profile.