I once stood over a beautiful tower farm, a literal waterfall of green life, ready to harvest. One side, bursting with crisp lettuce and vibrant kale. The other, lush, pungent cannabis plants in their final week. The morning started perfect. By noon, half the kale was a ghostly white, and the cannabis leaves were clawing in a desperate, mottled gasp. A simple miscalculation, a catastrophic misapplication of a shared nutrient reservoir, had turned my bounty into a bio-hazard. A $2,000 mistake, gone in a few hours. That day, I learned: You can’t fight a two-front war with one army. You have to pick your fighter and formulate accordingly. The physics of feeding roots suspended in air are unforgiving, and the rules change completely between a heat-tolerant herb and a fragile head of lettuce. This guide is my battle plan to make sure you never make my mistake. We’ll dive into the unseen forces, the chemical nuances, and the hard-won truths of balancing an aeroponic system. It’s a tightrope walk with no net, and you can’t afford to fail.

WARNING: Cannabis cultivation is federally illegal in some jurisdictions. This content and all associated data, including nutrient recipes and cultivation techniques, are provided for informational purposes only within jurisdictions where the cultivation and use of cannabis are legal. All equipment links are for 'ornamental plant research' only.

The Aeroponic Tightrope: Why 99% Fail at pH & EC

If hydroponics is a tranquil lake for your plant’s roots, then aeroponics is a high-pressure monsoon. A constant, fine mist bathing the roots for seconds at a time, followed by a period of total air exposure. This rapid cycle is what turbocharges growth, delivering a constant supply of oxygen to the root hairs, allowing them to absorb nutrients far more efficiently than in a traditional deep water culture (DWC) or soil system. But it’s also what makes the margin for error paper-thin. In a static reservoir, your root zone has a buffer. A large volume of water and nutrients can absorb shock, metabolize waste, and mitigate minor fluctuations. An aeroponic tower has no such cushion. The root zone is an open-air ecosystem, living and dying on the quality of a few short mist cycles a day.

This is why pH and EC are not merely suggestions; they are gospel. They are the twin pillars of your tower’s existence.

Understanding pH: The Gatekeeper of Nutrient Availability

pH is a measure of hydrogen ion concentration, a logarithmic scale that dictates the bioavailability of every single nutrient in your solution. It’s the key that unlocks the door to your plant’s feeding frenzy. If the pH drifts even a half-point outside the optimal range, that door slams shut, and your plants can starve in the presence of an otherwise perfect nutrient solution. This is known as nutrient lockout, and it’s a silent killer. I’ve had entire towers turn pale and yellow overnight from a sudden pH spike. You can have all the nitrogen in the world, but if the pH isn’t right, that nitrogen might as well be an inert gas.

Electrical Conductivity (EC): The Density of Your Nutrient Solution

EC (Electrical Conductivity) is the concentration of dissolved ionic salts in your water. Think of it as the density of the food in your nutrient soup. If your EC is too low, you’re starving your plants. If it’s too high, you’re force-feeding them so much salt that they can’t absorb water through osmosis, leading to “nutrient burn” where the tips of the leaves become scorched and brittle. For aeroponics, where roots are constantly exposed to air, the balance is even more critical. A high EC in a humid, root-dense environment can lead to salts accumulating on the roots themselves, an unwelcome crust that suffocates the plant. This delicate balance, this razor’s edge between feast and famine, is the single greatest challenge to master.

Case Study: The $2,000 Mistake of a Shared Reservoir

I’ll never forget one particularly hot summer in 2022. I’d set up a double-sided tower system, half lettuce, half cannabis, sharing a single reservoir (my first, and last, time doing this). I calibrated the nutrient mix for the lettuce, assuming it would be fine for the young cannabis plants. Mist cycles were perfect, EC was holding steady at 1.4 mS/cm, and the pH was a stable 6.5. Then, the inevitable happened. The cannabis, with its thirst for nitrogen and potassium, began a quiet war on the reservoir. Over 48 hours, it stripped the solution of its preferred nutrients, leaving behind the minerals it didn’t need. The pH began to skyrocket as it drew in more and more anions, while the EC stayed deceptively stable. My kale, a few feet away, started showing signs of manganese deficiency. The veins of its new leaves turned pale yellow, the edges curling into little claws. Meanwhile, the cannabis, still thriving on the a-la-carte menu it had created, showed no signs of stress. It was a silent battle of chemical priorities, with the kale as the first casualty. That morning, I lost 300 heads of lettuce. Never again. Now I know that what works for one plant can be poison for another.

Nutrient Split Screen: Lettuce/Kale vs. Cannabis Feed Charts

The foundational rule of aeroponics is simple: one size does not fit all. Let’s break down the nutritional needs of two of the most popular aeroponic crops. Think of it like this: a high-performance athlete and a couch potato both need food, but their caloric intake, macronutrient ratios, and vitamin requirements are worlds apart.

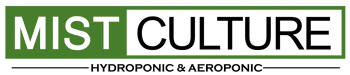

EC & pH Ranges for Different Crops

| Growth Stage | Crop Type | EC Range (mS/cm) | pH Range |

| Seedling to Harvest | Leafy Greens (Lettuce, Kale, Spinach) | 1.2–1.8 | 6.0–7.0 |

| Seedling/Veg | Cannabis (Legal Markets) | 1.4–2.2 | 5.8–6.5 |

| Flowering | Cannabis (Legal Markets) | 1.6–2.4 | 5.8–6.5 |

My field notes: Notice the subtle but critical differences. Leafy greens are much happier in a slightly more neutral to slightly alkaline pH. I’ve seen kale crash and burn when pushed below 6.0. Cannabis, meanwhile, craves a slightly more acidic environment, especially to pull in all the manganese it needs. The EC ranges are a direct reflection of a plant’s appetite. Cannabis, a heavy feeder, requires a richer nutrient solution, especially during the explosive vegetative and demanding flowering stages.

Micronutrient Chelates: The Unsung Heroes of Hydroponics

Micronutrients are the unsung heroes of any hydroponic nutrient solution. Just like vitamins in humans, plants need only a trace amount—but without them, your entire grow can collapse.

In hydroponic systems, nutrients are delivered in a water-soluble form. Unfortunately, micronutrients such as iron (Fe), copper (Cu), manganese (Mn), and zinc (Zn) can easily become “locked out” and unavailable to your plants, especially when pH drifts outside the ideal range.

This is where chelated minerals play a vital role. A chelate is an organic molecule that binds to a mineral ion, protecting it from reacting with other ions in the solution. This keeps the nutrient available to the plant across a wider pH range, improving uptake efficiency and yield consistency.

Micronutrient Chelates Breakdown

| Chelating Agent | Primary Mineral | pH Stability Range | Grower’s Verdict (Tested & Proven) |

|---|---|---|---|

| Fe-EDTA | Iron (Fe) | < 6.5 | The standard choice for most hydroponic setups. However, plants often show iron deficiency if pH rises above 6.5. Common issue in leafy greens. |

| Fe-DTPA | Iron (Fe) | < 7.5 | Ideal for alkaline tap water and higher-pH systems. Prevents iron lockout in cannabis and other sensitive crops. |

| Fe-EDDHA | Iron (Fe) | < 11.0 | Expensive but powerful. Works even in high-pH water. Recognizable by its red, wine-colored solution. Use when nothing else works. |

Real-World Example: Iron Deficiency in Romaine Lettuce

I once lost a full run of Romaine lettuce because I assumed all iron chelates were the same. My well water (pH ~7.2) rendered Fe-EDTA useless, and the roots suffered a severe iron lockout. The new leaves turned yellow—a classic chlorosis symptom. Switching to Fe-DTPA immediately solved the issue for the next cycle.

Further Reading

- Penn State Extension – Iron Management in Hydroponics

- University of Minnesota Extension – Micronutrient Bioavailability

Foliar vs Root Feeding: When to Mist vs. Soak

The beautiful thing about an aeroponic tower is that it’s essentially a two-stage delivery system. You can deliver nutrients directly to the roots via the mist, or you can supplement by spraying the leaves (foliar feeding). It’s not an either/or, but a critical tool for targeted intervention.

Emergency Foliar Feeding: A Grower’s Guerrilla Tactic

I’ll never forget the day a pump failed on one of my NFT systems. It wasn’t my aeroponic tower, but the same principles apply. The roots started to dry out, and the leaves began to wilt within hours. My first thought was a full crop loss. My second thought was a “guerilla grower hack.”

I ran to my nutrient stock, diluted my solution to 1/4 strength, and began hand-misting the leaves directly. This short-term foliar application allowed the plant to absorb a critical lifeline of nutrients and moisture, keeping them alive just long enough for me to get a replacement pump. Foliar feeding isn’t for daily use—you can burn leaves with too high a concentration—but for stress events, nutrient deficiencies, or for a specific, targeted mineral boost, it’s a game-changer. My personal rule is this: foliar feed at 1/4 strength, and never do it during the hottest part of the day.

Sterile vs Microbial Reservoirs: Deathmatch Data

The Risks of Sterile System Operation

This is the philosophical battleground of modern aeroponics: Do you nuke everything and run a sterile system, or do you cultivate a biome of beneficial microbes? The truth is, both approaches have their place, but one can be a house of cards. A sterile reservoir relies on a perfect, closed system. No rogue bacteria, no invading fungi. You sanitize everything, use hydrogen peroxide in your reservoir, and hope for the best. The moment a single pathogen—like the dreaded Pythium—gets in, it’s a race against time. The roots, without any beneficial microbes to defend them, are defenseless. You can lose an entire crop to root rot before you even see the first wilted leaf. This is Detonation Moment number two. A sterile reservoir is like an open wound in a dirty room.

Benefits of a Living Microbial Ecosystem

A healthy microbial reservoir, on the other hand, is a vibrant, living ecosystem. You introduce beneficial bacteria and fungi, like the mycorrhizae and Trichoderma species found in commercial inoculants. These microbes colonize the root zone, forming a protective barrier against pathogens. They also break down nutrient salts into more bio-available forms, increasing a plant’s efficiency. The trade-off? You have to maintain that ecosystem. It needs proper pH, temperature, and aeration to survive. But the data doesn’t lie: in my experience, a healthy microbial reservoir is far more resilient. My first big Pythium outbreak was in a sterile system. I’d cleaned the tower with a 10% bleach solution and thought I was safe. I wasn’t. The moment the pathogen entered, it had free reign. Roots turned brown and slimy, and I lost the entire run in under a week. My current system, inoculated with beneficial microbes, has weathered minor contamination events with barely a hiccup. I’ve seen it with my own eyes: a healthy root biome fights back.

pH Drift Takedown: 3 Zero-Cost Hacks

pH drift is insidious. It’s like a slow leak in your tire: you don’t notice it until the handling is terrible and the rim is scraping the pavement. My worst disaster was when I was out of town, and the pH in my reservoir drifted from a perfect 6.0 to a deadly 8.5. It wasn’t just that the nutrients were locked out, the roots themselves were scorched. The takeaway: you need to be proactive. Here are my three favorite zero-cost hacks for managing pH drift, hard-won from a decade of battling the invisible enemy.

Water Source Acclimatization Technique

Don’t just dump tap water into your reservoir. Your tap water’s pH and alkalinity can change dramatically. Fill a separate container and let it sit for 24-48 hours with an air stone. This allows the chlorine to off-gas and the pH to stabilize before you add it to your main system. It’s a simple, free step that dramatically reduces pH shock.

Reservoir Volume Management Strategy

It seems counterintuitive, but letting your reservoir level drop before topping it off with a fresh, pre-calibrated nutrient solution helps. As your plants grow, they strip out ions, which changes the pH. Topping off with a small amount of water from your storage tank will dilute the remaining solution. Let it run for a few hours, then take your readings and add your concentrates.

Utilizing the pH “Wiggle” Zone

Most beginner guides tell you to hold your pH steady at 6.0. Don’t. Instead, let your pH fluctuate naturally within the optimal range (e.g., 5.8-6.5 for cannabis). Different nutrients are absorbed best at slightly different pH points. Letting the pH “wiggle” allows the roots to absorb a wider spectrum of elements more efficiently. It’s a little scary at first, but it works.

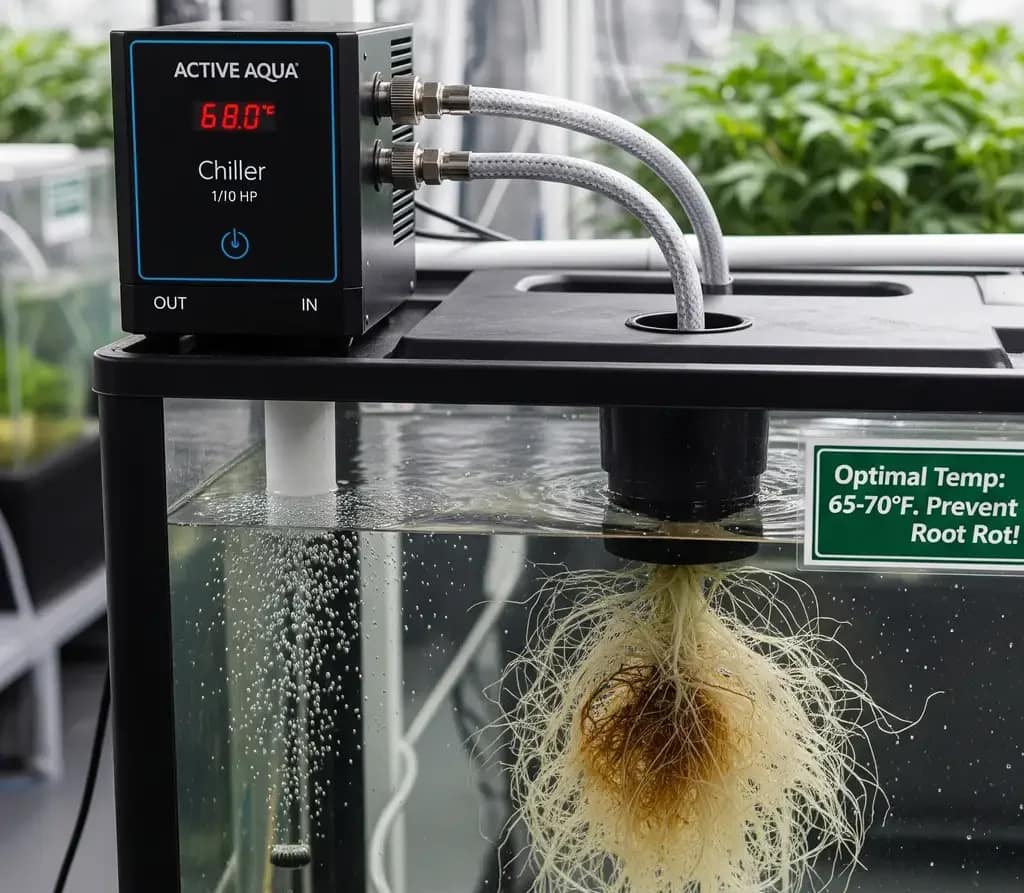

Reservoir Temp Armor: Why Hot Roots Kill Crops

Temperature is the ultimate silent killer. You can have a perfectly balanced nutrient solution, but if the water is too warm, your crop is on a fast track to ruin. The physics is simple: warmer water holds less dissolved oxygen (DO). Your roots need a constant supply of oxygen to respire and absorb nutrients. Without it, they literally suffocate, and become a breeding ground for opportunistic pathogens like Pythium.

I learned this the hard way when a chiller failed in the middle of a brutal heat wave. I lost about $2,000 in product in 72 hours. My reservoir hit 85°F. The roots, once pearly white and vibrant, turned a slimy, brown mess. I now have a reservoir temp monitoring system and a backup power plan. My personal rule: keep your reservoir between 65-68°F (18-20°C). Below that, growth slows. Above that, you’re rolling the dice on root rot.

Disaster Recovery: Salvaging Scorched Crops

Detonation Moment 3: So, you’ve made a mistake. Your crop is looking sickly, leaves are yellowing or scorched, and panic is setting in. Don’t give up. The beauty of aeroponics is the speed of recovery. You can flush the entire system and reset in a matter of hours, something impossible in soil. The key is to act fast.

Step-by-Step System Recovery Protocol

- Drain Everything: Your first priority is to flush the contaminated nutrient solution. Drain the entire reservoir and all lines. If your reservoir is large, you might need a submersible pump for this.

- Rinse the Roots: With clean, pH-neutral water, gently mist the roots to wash off any excess salts or contaminants. Let them drip dry for an hour or so, exposed to the air.

- Clean the System: Clean out your reservoir. I recommend a simple wash with hot water and a mild, pH-neutral soap. Then a quick rinse with a weak hydrogen peroxide solution (3 mL of 3% hydrogen peroxide per liter of water) to sanitize.

- Recalibrate and Restart: Prepare a new, fresh batch of nutrient solution at half-strength of what you’d normally use. Calibrate the pH and EC perfectly. Put your plants back on their timer settings and monitor them like a hawk for the next 24 hours. They will show signs of recovery quickly if you’ve caught the problem in time.

The system is unforgiving, but it is also fast. The lessons I learned from my mistakes are now the foundation of a successful business. I’ve taken the art of aeroponics, married it to the science of nutrient delivery, and learned to listen to what the plants are telling me. Now, you can too.

Frequently Asked Questions About Aeroponic Nutrients

Q: What is the main difference in nutrient needs between leafy greens and cannabis in an aeroponic system?

A: Leafy greens like lettuce and kale have a lower nutrient demand and thrive in a slightly higher pH range (6.0-7.0) and lower EC range (1.2-1.8 mS/cm). Cannabis, a much heavier feeder, requires a richer nutrient solution (higher EC) and prefers a slightly more acidic pH range (5.8-6.5) to efficiently absorb key minerals, especially during its vegetative and flowering stages.

Q: Why is pH so critical in aeroponics, and what is nutrient lockout?

A: pH is critical because it determines the bioavailability of all nutrients in the solution. If the pH is outside the optimal range, a plant cannot absorb certain elements, even if they are present in the water. This is known as nutrient lockout. In aeroponics, with no buffer, a pH swing can lead to nutrient lockout and catastrophic crop loss in a matter of hours.

Q: Can I use one nutrient reservoir for different types of plants, like lettuce and peppers?

A: It is not recommended to use a single reservoir for different plants with wildly different nutrient requirements. A plant with a higher appetite (like peppers) will strip the solution of its preferred nutrients, causing pH swings and nutrient deficiencies for the lighter-feeding plants (like lettuce). This can lead to a domino effect of chemical imbalances and crop failure.

Q: What is the best way to manage reservoir temperature to prevent root rot?

A: The ideal reservoir temperature is between 65-68°F (18-20°C). Above 70°F, the dissolved oxygen in the water plummets, creating a perfect environment for pathogens like Pythium, which causes root rot. For hobbyists, insulating the reservoir or using frozen water bottles can help. For larger systems, a water chiller is the most reliable way to maintain a stable, cool temperature.

Gear for the Aero-Gladiator: Essential Equipment

A true alchemist is only as good as their tools. If you’re serious about mastering aeroponics, don’t skimp on the essentials. Here are the field-tested tools I rely on.

Precision Measurement Tools: pH & EC Meters

The cornerstone of your operation. I’ve tried the cheap strips and the flimsy digital pens. They’re a false economy. Accuracy is non-negotiable.

Solves: The constant dance of measuring pH, EC, and temperature with separate, unreliable devices. Apera is more robust.

Verdict: “It’s waterproof, accurate to within a hair’s breadth, and the replaceable probe means it lasts years. Saved me from countless pH swings. Cheaper than replacing two pumps.”

Premium Nutrient Lines and Formulations

You need a high-quality, chelated nutrient blend that works in your water chemistry. This is the difference between a thriving crop and a lackluster one.

Solves: Chelate conflicts and nutrient lockout. The three-part system allows you to fine-tune your NPK ratios for different crop stages.

Verdict: “Saved my Swiss chard from iron lockout with its DTPA formulation. My cannabis roots crave it. It’s a precise, forgiving solution that feels custom-built.”

Microbial Inoculants for Root Defense

If you’re running a living system (and you should be), this is your insurance. It’s the army that defends your roots from a silent invasion.

Solves: Pathogen attacks and slow nutrient uptake. Mycorrhizal fungi form a symbiotic relationship with your roots, creating an extended root system for better nutrient absorption.

Verdict: “After a disastrous Pythium outbreak, this rebuilt my root biome from scratch. It’s now a non-negotiable in my towers. My roots have never been whiter or more robust.”

Climate Control: Water Chillers Systems

This is the big kahuna, the final piece of the puzzle for temperature control. I once lost a harvest due to a reservoir overheating. Don’t be me.

Solves: Overheating reservoirs, low dissolved oxygen, and root rot. It silently maintains your optimal water temperature, no matter how hot your grow room gets.

Verdict: “An expensive but essential piece of kit. My chiller failure caused $2k in crop loss. This unit has been a silent guardian ever since.”

Conclusion: From Warfare to Mastery

My journey into aeroponics wasn’t built on a string of successes; it was forged in the costly, frustrating, and utterly devastating failures that come with misunderstanding this beautiful, brutal science. That ghostly white kale and those clawing cannabis leaves taught me more than any textbook ever could. They taught me humility and respect for the delicate physics of feeding roots suspended in air.

Mastering your tower isn’t about finding a single magic formula. It’s about becoming a keen observer, a diligent scientist, and a responsive caregiver for your plants. It’s understanding that the razor-thin margins of pH and EC are your new commandments, and that vigilance is your most valuable tool. The true secret isn’t in a bottle of nutrients—it’s in the consistent, daily practice of monitoring, adjusting, and learning to speak your plant’s language.

The difference between a barren tower and a waterfall of green life often comes down to the foundational skills, the core pH balancing techniques that keep the nutrient lockout at bay. Remember that you’re not just running a system; you’re curating an ecosystem. Whether you choose a sterile approach or embrace the chaotic beauty of a living reservoir, your attention to detail dictates your success.

So, take this battle plan—forged from my mistakes—and arm yourself. Invest in a reliable meter, choose your nutrients wisely, and never underestimate the silent killer of reservoir heat. Listen to what the leaves are telling you, act quickly when things drift, and trust that the tightrope walk gets easier with every harvest.

Your tower is waiting. Now you have the knowledge to feed it perfectly.